Piping Stress Analysis

The use of finite element softwares allows to solve all the issue about components subjected to pressure that can not be directly analyzed by formula, otherwise a large oversizing must be introduced into the design process.

The use of finite element softwares allows to solve all the issue about components subjected to pressure that can not be directly analyzed by formula, otherwise a large oversizing must be introduced into the design process.

VCE Engineering offers a design service by means of finite element analysis encompassing from piping stress analysis to single piping component, from pressure equipments (branches, nozzles or support) to a complete evaluation of an entire vessel.

Among the most widely used international standards, as well as customer specific standard, include:

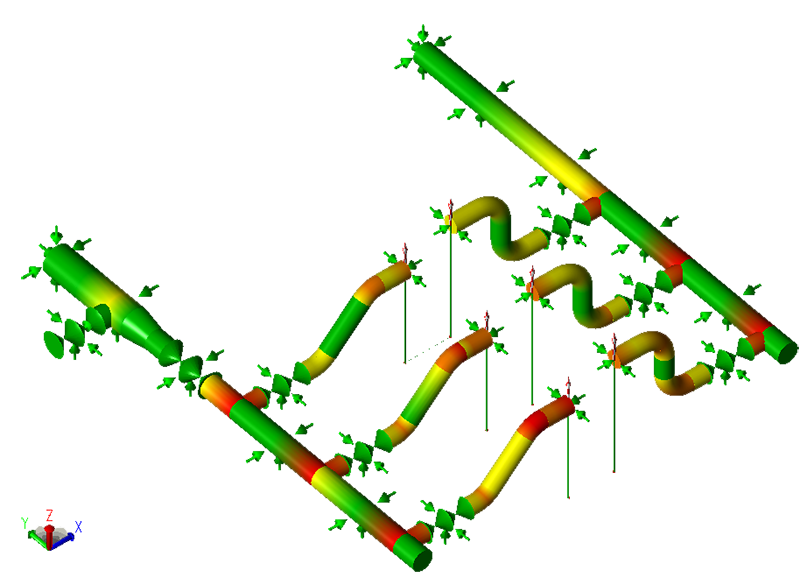

The analysis are carried over by means of static and dynamic analysis (modal analysis, response spectrum, time history) in order to evaluate properly the seismic effect or the effects due to harmonic loads (wave, pulse etc…).

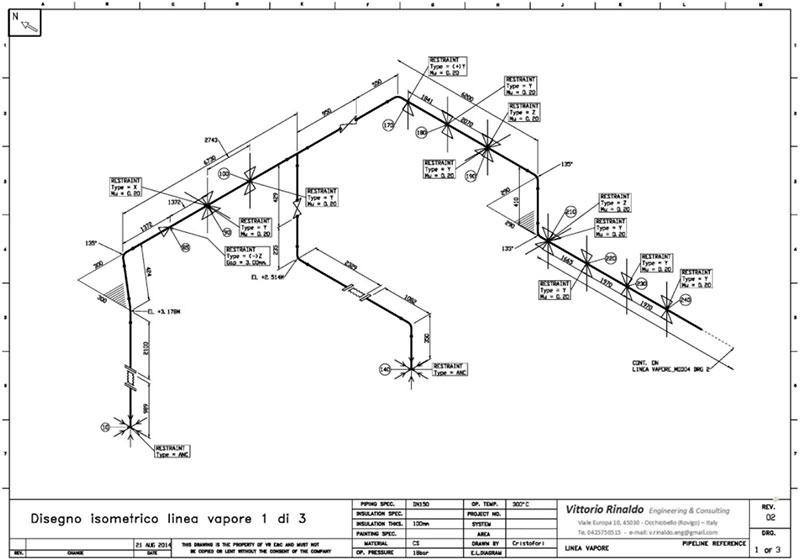

The verification are performed by using specific software such as CAESAR II. Among the activities we perform also the design constraints and structural elements necessary for the maintenance of pipes and equipment.

The analysis reports are integrated by means of stress isometric drawings, the job may include also the preparation of detail drawings for construction and execution of structural verification necessary for proper installation and operation of the system.

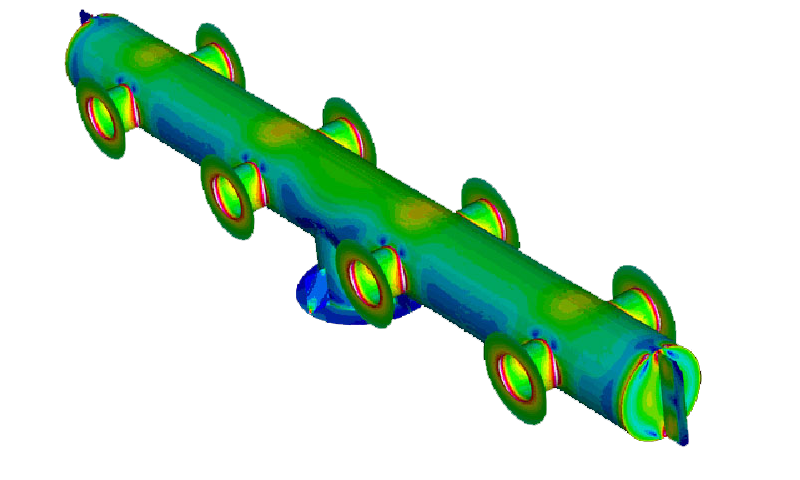

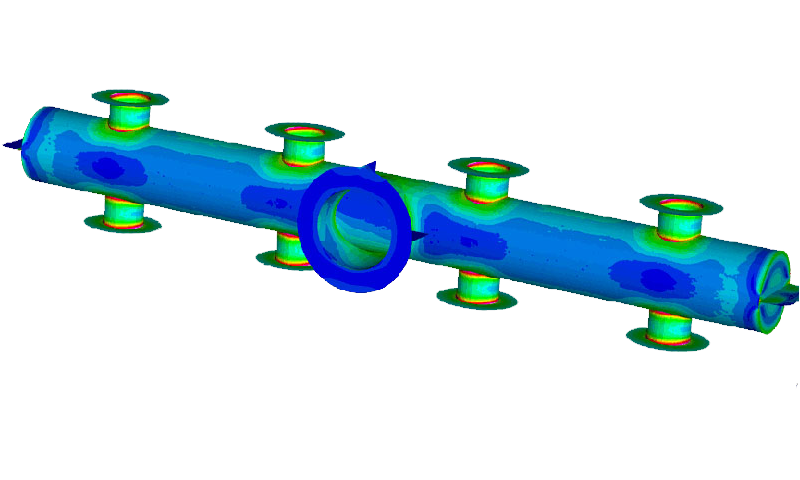

Whenever the design by formula fails to simulate satisfactorily the geometry under examination of a pressure equipment, or in case it is necessary to optimize the design of an apparatus or a part of it, it is possible to design or verify the said component by means of the Finite Element Analysis.

The pressure equipment components are analysed and post-processed accorordingly to the standard ASME VIII div. 2 part 5 or EN 13445.

The analysis can be carried over by using 3-D elements or shell elements, also by means of software dedicated to the analysis of pressure parts, like NozzlePRO.

Moreover, by using the FEA method tipically by means of 3-D axysymmetric elements, also thermal and structural studies on Hot-Box are performed as per standard ASME VIII div. 2.

Phone: +39 041 997612

Fax: +39 041 997612

E-Mail: info@vce-eng.com